Company news

当前位置:首页>>NEWS>>Company news

当前位置:首页>>NEWS>>Company news

Company news

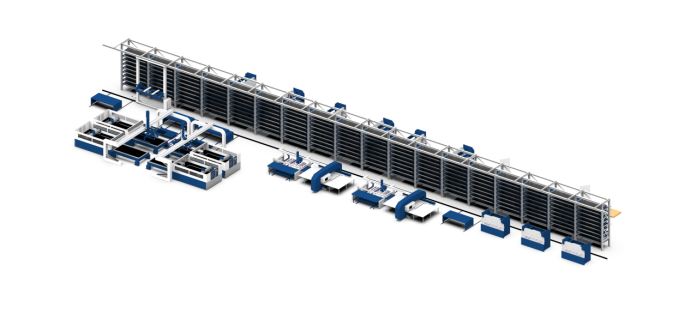

In the modern sheet metal fabrication industry, efficient management and supply of raw materials have always been critical factors affecting production efficiency. Traditional manual storage methods not only occupy significant floor space but also require substantial human resources for management, severely limiting production efficiency and flexibility. The large-scale multi-tower storage system launched in 2020 by Yangzhou Antil Automation, after several years of R&D and innovation, has completely transformed this scenario, providing comprehensive upgrade solutions for sheet metal fabrication enterprises.

Space Optimization and Cost Savings

Large-scale multi-tower storage system adopts vertical three-dimensional storage design, making full use of factory height space. Compared with traditional flat storage, it can save up to 70% of floor area. This feature is particularly valuable in industrial areas with high rental costs, significantly reducing operational expenses for enterprises. Meanwhile, the application of automation systems greatly reduces the need for manual intervention. Tasks that previously required multiple workers—such as material handling, searching, and loading—can now be accomplished with just a few technicians monitoring the system, achieving over 80% savings in labor costs.

Quantum Leap in Production Efficiency

The seamless integration of multi-tower storage system with production lines enables a direct "raw material to equipment" supply model. Through intelligent scheduling algorithms, the system can automatically identify production needs and accurately complete the entire process of sheet metal retrieval, transportation, and loading within minutes—a task that traditionally took hours. The 24/7 automated operation ensures continuous and efficient operation of production lines, with overall productivity increasing by 40%-50%.

Unparalleled Production Flexibility

One of the most outstanding advantages of large-scale multi-tower storage system is its exceptional production flexibility. The system can store and manage hundreds of different specifications of sheet metal while monitoring inventory status in real time through intelligent software. Even during mass production, urgent orders can be easily inserted. The system automatically adjusts material supply priorities to ensure urgent tasks are processed first without affecting overall production schedules. This flexibility allows enterprises to respond quickly to changing customer demands, gaining a competitive edge in fierce market competition.

Intelligent Management and Quality Control

The multi-tower storage system is equipped with advanced Warehouse Management Software (WMS), enabling precise inventory management, automatic replenishment reminders, and data analysis functions. The entire process of each sheet's storage—including inbound, storage, and outbound—is fully recorded, ensuring material traceability. At the same time, automated handling avoids potential scratches or deformations caused by manual operations, significantly improving product quality consistency.

Conclusion

The large-scale multi-tower storage system is not just an upgrade of storage equipment but a core component of intelligent transformation for sheet metal fabrication enterprises. It addresses pain points in traditional models such as space waste, low efficiency, and insufficient flexibility, providing enterprises with sustainable competitive advantages. In the Industry 4.0 era, investing in automated multi-tower storage system has become an inevitable choice for sheet metal fabrication enterprises to enhance competitiveness and achieve high-quality development.