Industry news

当前位置:首页>>NEWS>>Industry news

当前位置:首页>>NEWS>>Industry news

Industry news

Customer: NEDFON, Guangdong, China

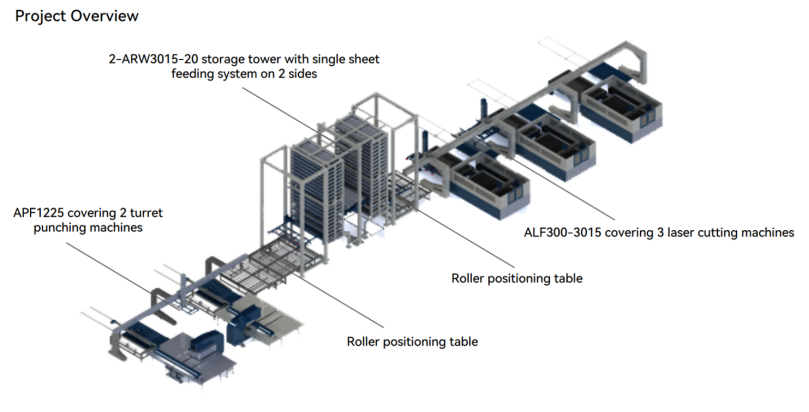

Project: 2-ARW3015-20 + ALF300-3015 + APF1225

Guangdong NEDFON, a leading manufacturer in the ventilation industry, required an advanced automated sheet metal storage and processing system to integrate multiple machines efficiently. The challenge was to seamlessly connect three laser cutting machines and two turret punch presses using a single dual-tower storage system while maintaining high production efficiency.

Key challenges:

Integration complexity: coordinating 5 machines (3 laser cutters + 2 turret punching machines) with 1 dual-tower storage system.

Production bottlenecks: traditional storage systems could not keep up with the high-speed material handling demands of multiple machines.

Diverse material needs: some sheets required processing, while others only needed storage, necessitating a flexible solution.

Innovative Solution:

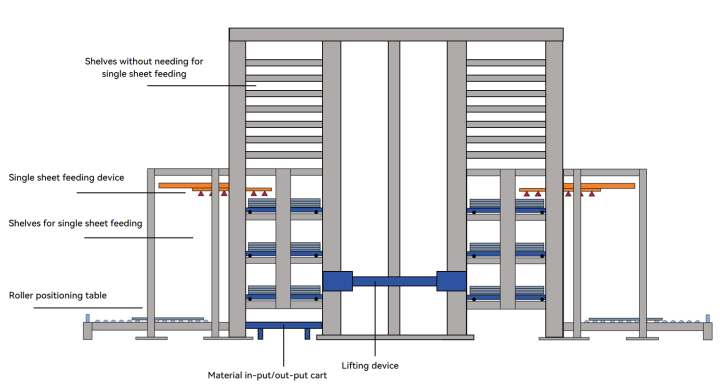

Yangzhou Antil Automation designed a customized dual-tower storage system (2-ARW3015-20) with the following breakthroughs:

Dual-side single sheet feeding:

One side served 3 laser cutting machines with single-sheet feeding. The other side supplied 2 turret punching machines with single-sheet feeding, significantly improving material transfer efficiency.

Zoned storage design:

Dedicated areas for processing-ready sheets (single-sheet feeding). Separate zones for storage-only sheets, optimizing space and workflow.

High-speed material handling:

The system eliminated traditional bottlenecks, ensuring smooth material flow to all five machines without delays.

Results & benefits:

Seamless integration: all 5 machines operated harmoniously with a single automated storage system.

Enhanced efficiency: Dual-side feeding and intelligent zoning maximized throughput, surpassing traditional storage and material feeding limitations.

Customized flexibility: The hybrid storage design met both processing and pure storage needs, adapting to dynamic production demands.

Conclusion:

Yangzhou Antil Automation’s innovative approach solved NEDFON’s complex automation challenges, delivering a high-efficiency, fully integrated sheet metal processing line. This case demonstrates how tailored automation solutions can transform multi-machine production environments, setting a new benchmark for smart manufacturing.

ALG300-3015 covering 3 laser cutting machines

APF1225 covering 2 turret punching machines

Date: 2025.7.7