咨询热线:

+86-400-0018-166

公司地址:

Pangu industrial concentration zone, Liuji Town, Yangzhou City

Email:

info@antil.com.cn

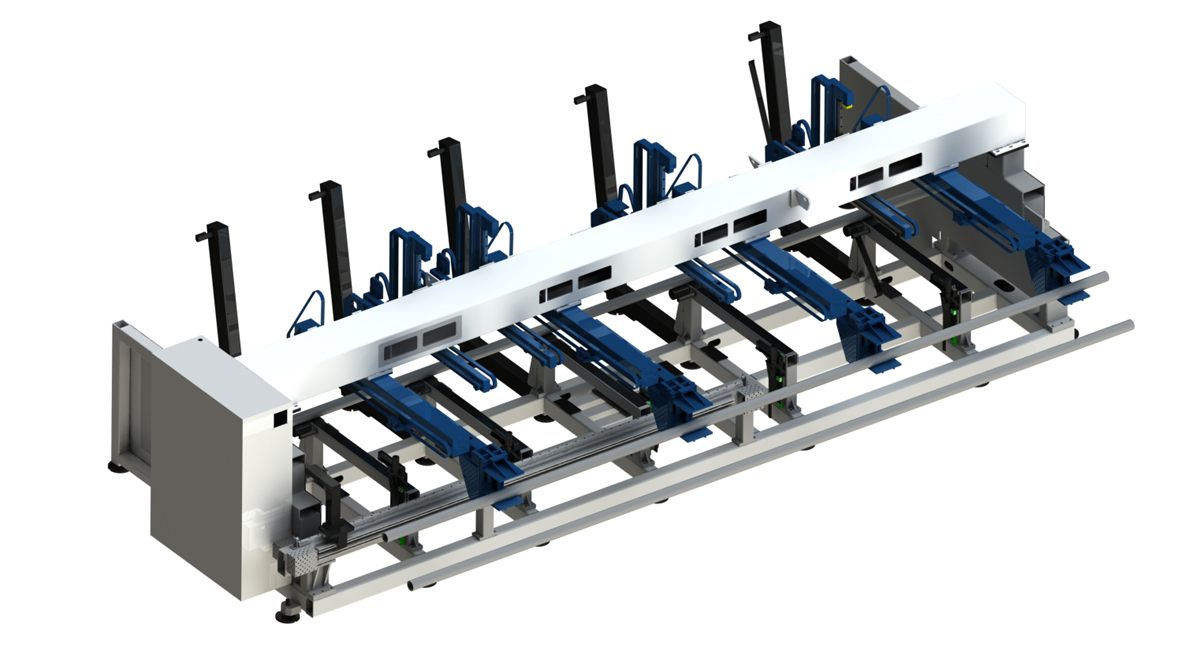

The system consists of an at series laser pipe cutting machine for automatic feeding, laser pipe cutting machine and safety protection facilities (optional). The three-dimensional of its general assembly is shown in the figure.

Product features:

1) Press one key to return the remaining materials;

2) Straighten the rectangular tube;

3) No one is waiting for loading, and the batch production of steel pipes of different specifications can be completed super economically;

4) The automatic single pipe removal mechanism returns the excess steel pipe to the stock stack;

5) The structural principle of the feeding system is to use the roller table to cooperate with the cylinder to send the pipe to the feeding position of the laser pipe cutting machine;

6) Improve work safety, reduce the risk of injury and reduce the workload of staff;

7) The operation interface is simple, and it can be operated after 3 days of zero basic staff training;

8) Servo full bus communication, absolute encoder does not need back reference;

9) The surface of the lifting belt of the material stack is hardened by Pu, with good wear resistance;

10) Multiple structures adopt motor to drive gear and rack, with good synchronization;

| unit | parameter | ||

| Minimum feeding pipe length | mm | 3000 | |

| Maximum feeding pipe length | mm | 6000 | |

| Pipe section side length (or diameter) | mm | 20-220 | |

| Feeding cycle time | s | ≤15 | |

| Feeding time of single pipe | s | ≤80 | |

| Sectional area of material stack | m ^2 | 0.3 | |

| Maximum loading weight | kg | 3000 | |

| Maximum single weight | kg | 350 | |

Note: pipe straightness ≤ 20mm

Automatic feeding of at622 laser pipe cutting machine

稳定运行,精密度高

运转高、运行快

噪音小、降低磨损

节约成本、寿命长

可根据客户要求定制