咨询热线:

+86-400-0018-166

公司地址:

Pangu industrial concentration zone, Liuji Town, Yangzhou City

Email:

info@antil.com.cn

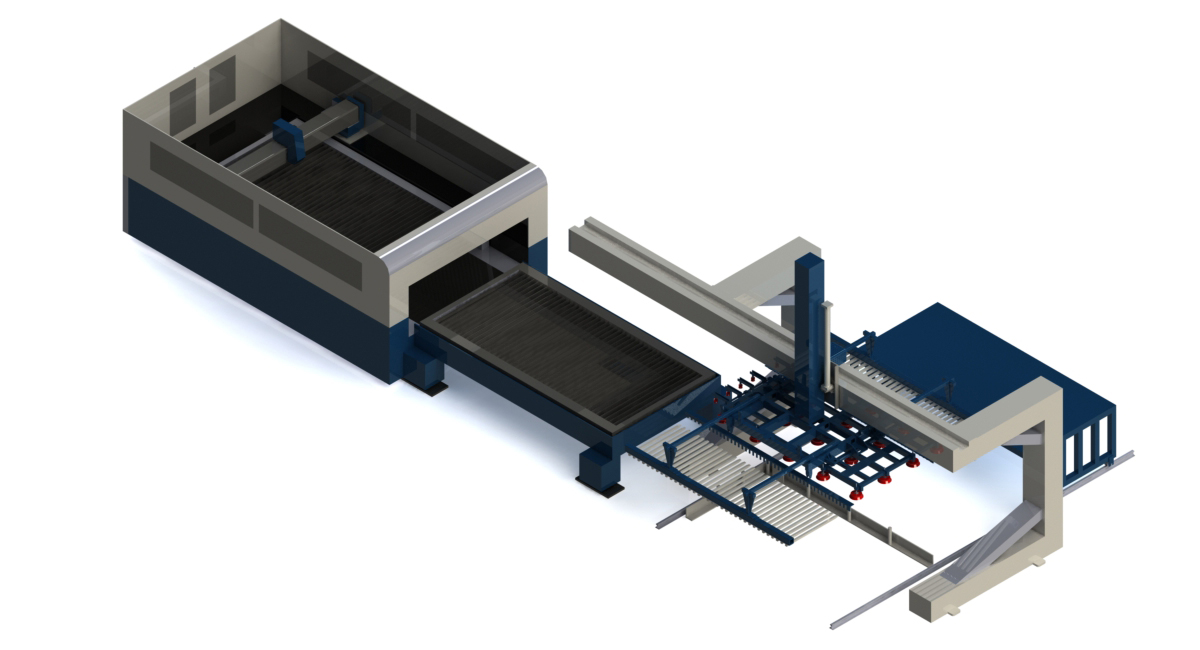

The system is composed of an alg200 laser loading and unloading robot, a finished product trolley, a plate pre positioning device, a 3015 laser cutting machine and a safety fence light curtain (optional). The three-dimensional of the general assembly is shown in the figure.

Product features

1) No one is waiting for loading and unloading to complete medium-sized to large-scale mass production economically;

2) Automatic plate thickness measurement, plate separation function and double-layer plate detection function;

3) The structure principle of the feeding system is that the vacuum suction device is used as the tooling of the robot to replace the traditional manual feeding;

4) Improve work safety, reduce the risk of injury and reduce the workload of staff;

| unit | parameter | ||

| Thickness of upper and lower material plates | mm | 1-6 | |

| Maximum feeding plate size | mm | 3000×1500 | |

| Minimum feeding plate size | mm | 1250×1250 | |

| Maximum moving speed of horizontal movement X-axis | m/min | 32 | |

| Maximum moving speed of vertical movement Z axis | m/min | 15 | |

| Maximum running speed of gear shaper | m/min | 15 | |

| X-axis travel | mm | 5300 | |

| Z-axis travel | mm | 900 | |

| Maximum workpiece weight | kg | 200 | |

| Maximum load of hopper car | kg | 3000 | |

| Maximum moving speed of hopper car | m/min | 12 | |

| Air supply pressure | MPa | 0.55 | |

| Overall dimensions of machine tool | length | mm | 7300 |

| width | mm | 3700 | |

| height | mm | 4200 | |

Alg200 laser loading and unloading robot

稳定运行,精密度高

运转高、运行快

噪音小、降低磨损

节约成本、寿命长

可根据客户要求定制