咨询热线:

+86-400-0018-166

公司地址:

Pangu industrial concentration zone, Liuji Town, Yangzhou City

Email:

info@antil.com.cn

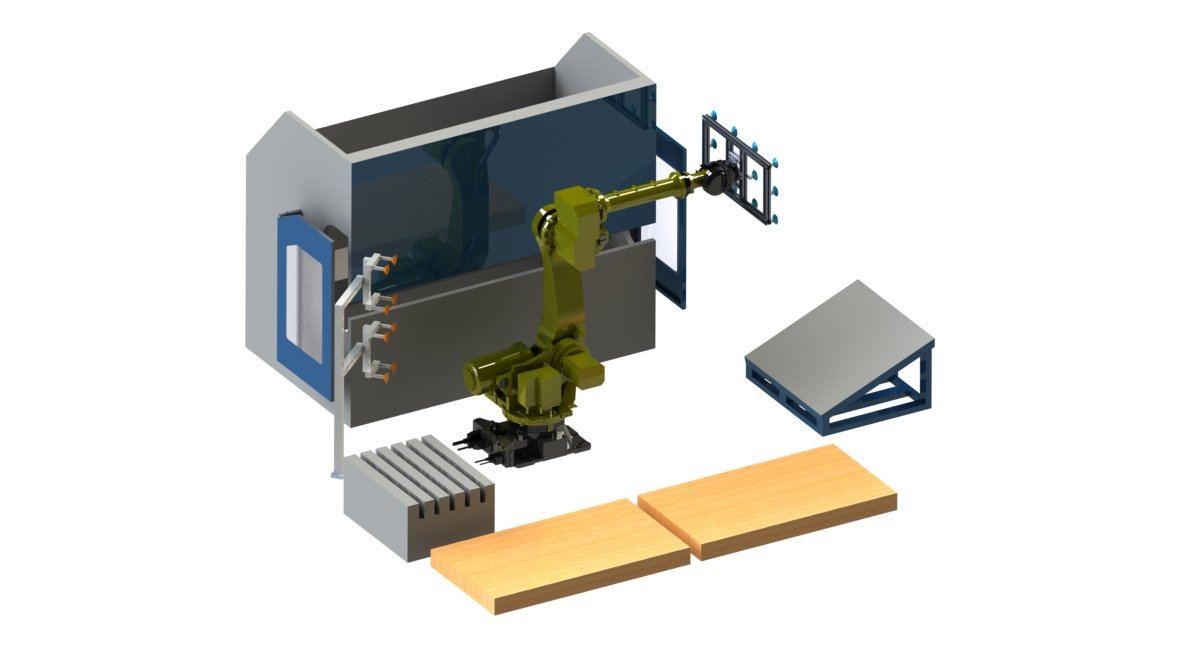

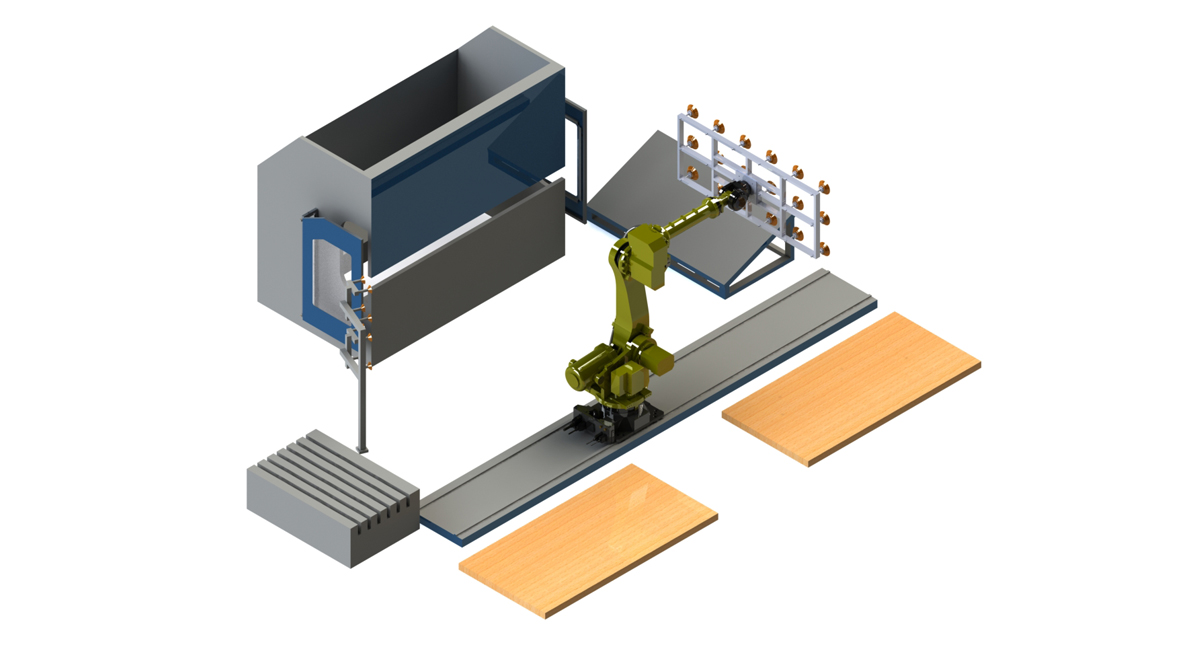

The production line is designed and developed according to the work to be completed by Party A and the on-site working environment. The loading, positioning, correction, bending following, stacking and other processes of sheet metal are completed by robot. The whole system has a good operation interface, which is convenient for the operator to use;

Using the six axis robot, a bending system is designed, which can realize the bending operation in the form of workstation.

The system includes: raw material positioning auxiliary platform, bevel positioning platform, finished product stacking platform (provided by the customer), flanging frame, robot, CNC bending machine (provided by the customer), tooling, robot base and safety protection measures (optional), etc.

6-axis bending

7 axis bending

| type | R-2000iC/165F | |

| Action type | Multi joint type | |

| Degree of freedom of motion | 6 | |

| Rated load weight | 165KG | |

| Maximum speed | J1 axis rotation | 130º/s |

| J2 axis rotation | 115º/s | |

| J3 axis rotation | 125º/s | |

| J4 axis rotation | 180º/s | |

| J5 axis rotation | 180º/s | |

| J6 axis rotation | 260º/s | |

| Scope of work | J1 axis | 370º |

| J2 axis | 136º | |

| J3 axis rotation | 312º | |

| J4 axis rotation | 720º | |

| J5 axis rotation | 220º | |

| J6 axis rotation | 720º | |

| Maximum working radius | 2655mm | |

| Weight of robot body | 1090KG | |

| Repeat positioning accuracy | ±0.05mm | |

| Degree of protection | IP65 | |

| Operating ambient temperature | 0-45℃ | |

| Operating ambient humidity | Below 75% RH (no condensation) | |

| vibration acceleration | 4.9m/s² | |

| Input power (average power consumption) | 12kVA(2.5kW) | |

| Driving mode | AC servo motor drive | |

R-2000iC/165F

| type | R-2000iC/210F | |

| Action type | Multi joint type | |

| Degree of freedom of motion | 6 | |

| Rated load weight | 210KG | |

| Maximum speed | J1 axis rotation | 130º/s |

| J2 axis rotation | 115º/s | |

| J3 axis rotation | 125º/s | |

| J4 axis rotation | 180º/s | |

| J5 axis rotation | 180º/s | |

| J6 axis rotation | 260º/s | |

| Scope of work | J1 axis | 370º |

| J2 axis | 136º | |

| J3 axis rotation | 312º | |

| J4 axis rotation | 720º | |

| J5 axis rotation | 220º | |

| J6 axis rotation | 720º | |

| Maximum working radius | 2655mm | |

| Weight of robot body | 1090KG | |

| Repeat positioning accuracy | ±0.05mm | |

| Degree of protection | IP65 | |

| Operating ambient temperature | 0-45℃ | |

| Operating ambient humidity | Below 75% RH (no condensation) | |

| vibration acceleration | 4.9m/s² | |

| Input power (average power consumption) | 12kVA(2.5kW) | |

| Driving mode | AC servo motor drive | |

R-2000iC/210F

Joint series bending

Joint series 2

稳定运行,精密度高

运转高、运行快

噪音小、降低磨损

节约成本、寿命长

可根据客户要求定制